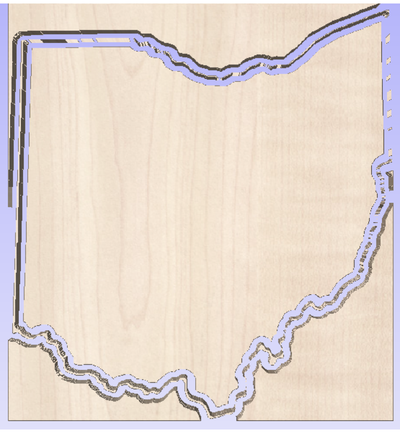

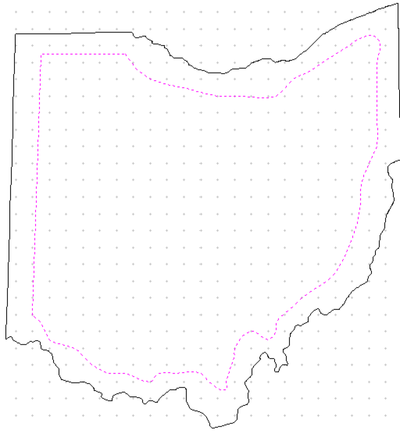

A cousin requested a cutting board in the shape of Ohio, and then another requested Arizona. The first step is to find an outline of the state. It does not have to be a .svg because the software can take .jpg or .png and turn them into vectors. You do not want something with too much detail, I am using a ¼” bit to cut out the shape, so fine details would be lost. The first issue I encountered was that the software read the outline as two vectors, even though it is a thin line. Luckily I could select one of the vectors and delete it. Next step is to draw lines for the groove inside the shape. This is not going to be “perfect” because of the irregularity of the shapes of states, but using the straight line tool and the curve tool, it comes out okay. Sometimes it is difficult to tell how far from the edge it will be, even with guide dots. Export the cut files, get it all lined up on the CNC router and go. Since the board is 0.80” thick, it will take 7 passes to cut through. Unfortunately on pass 3, the router shifted in the X direction, just by a little. But this meant it was trying to cut through 3 “layers” of cuts at once, and that is not good. Also the board would now have a lip to cut/sand off. I stopped it and sent it back to (0,0) and it was in a different X place than when started. I re-zeroed and finished that board but will have detail work to do. I turned the machine off and on, then zeroed the tip again for the second board. This one came out alright. I don’t know why it change zero half way through the first cut. Time to sand and oil.

Next up is to try Arizona.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

December 2022

Categories |

RSS Feed

RSS Feed